To buy several parts, you must add them one part at a time to the cart.

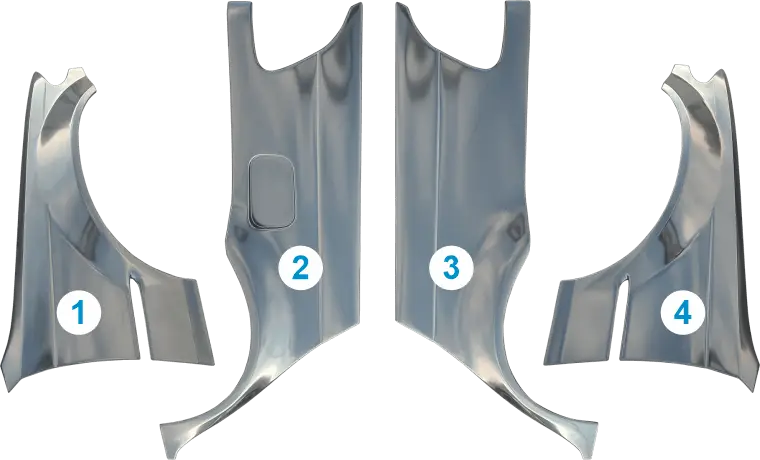

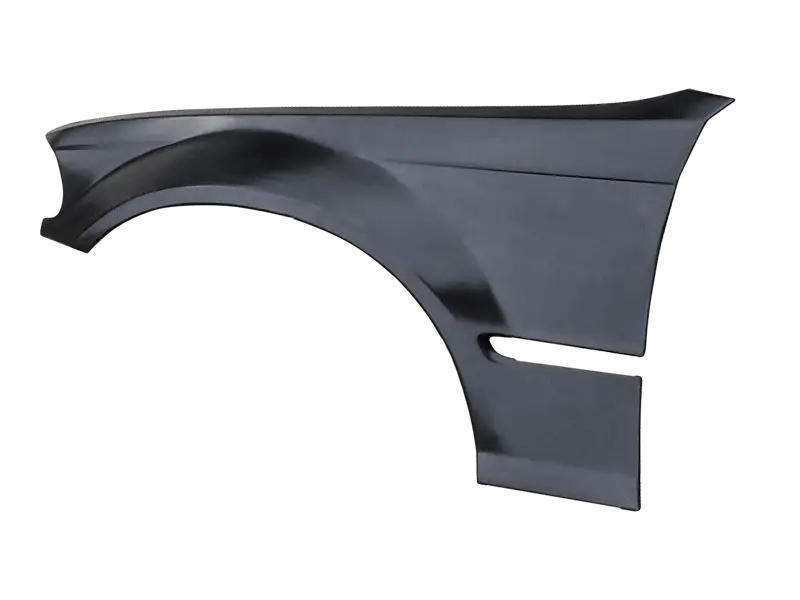

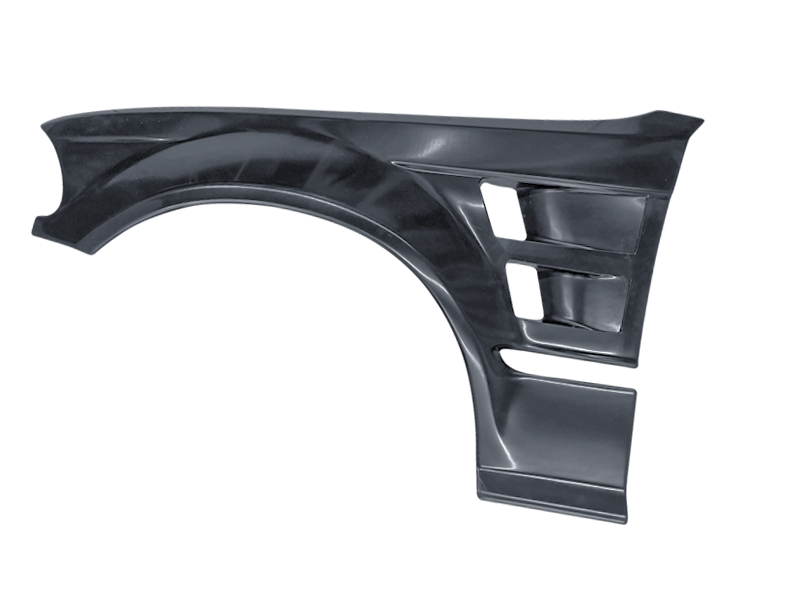

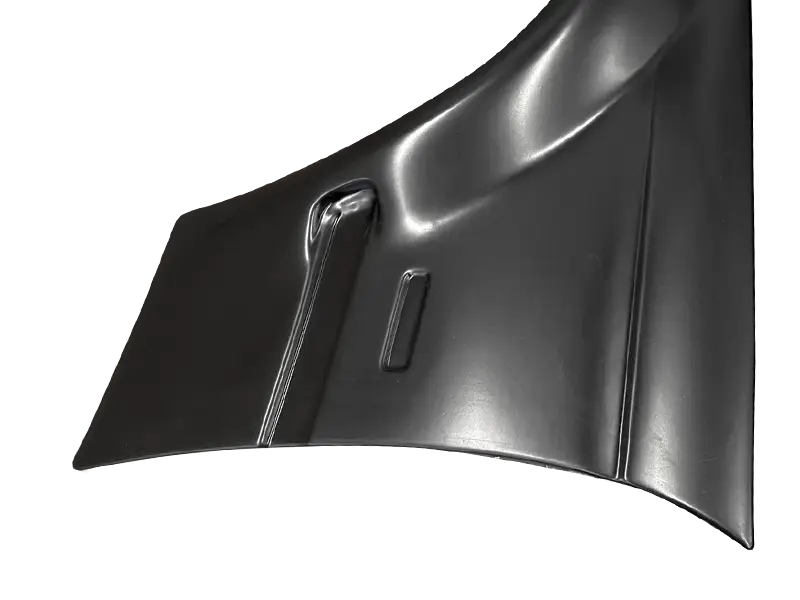

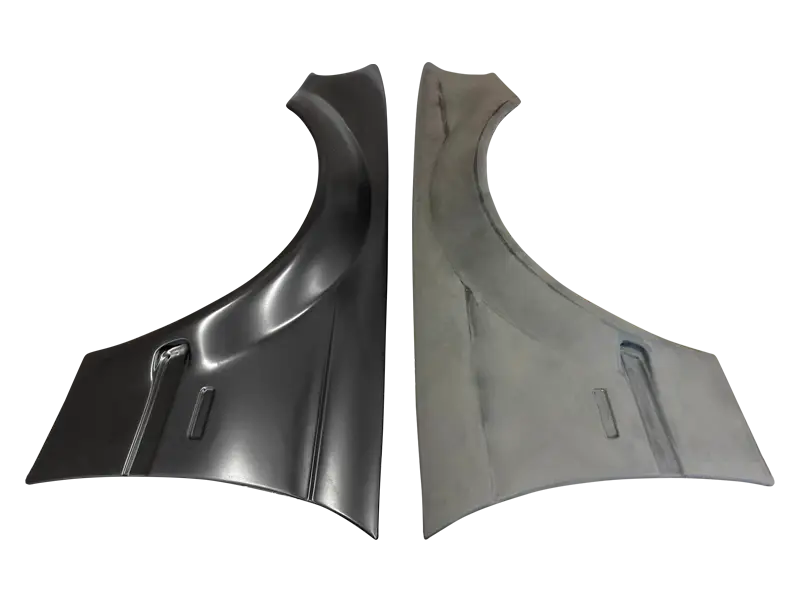

Finished products

1 - right front fender flare; 2 - right rear fender flare; 3 - left rear fender flare, 4 - left front fender flare.

1 - right front fender flare; 2 - right rear fender flare; 3 - left rear fender flare, 4 - left front fender flare.

Bumper covers are included

- Mage of ABS plastic

- From the manufacturer

- Online assistance with installation

- From ABS plastic

- From the manufacturer

- Online assistance with installation

Advantages, opportunities, benefits

The wheelbase of the car is wider

Increase the width by 60 mm. High stability and controllability of the car. Win!

Premium material ABS plastic

Much stronger than fiberglass. Does not deform after impact. No need to adjust, bend, putty. Does not rust, does not rot, does not shrink.

As new - with widebody and lip

More aerodynamics. More sports and aggression. This is not an old car anymore, this is a new BMW e46.

Masks flaws

Covers the front and rear wings. Metal parts and rust are hidden under the plastic. Saving money - replaces body repairs for a while.

You save on installation

The kit has a non-extreme extension. Metal parts can be changed or not changed. Ready to install. You can do it yourself.

You save on finishing

The kit can be painted. The kit can be left unpainted. Ideal for stickers: advertising cars, sports cars, films.

You save on repairs

Quick and easy repair. Like a regular bumper. Minimum filler. “Meatted” option for priming readiness.

BMW Fender Protection from:

Paint chips, rust and corrosion, chemicals, rocks on the road, - hitting the curb.

About our production and our history

In 2018, we started the first thermoforming experiments.

Many people said that nothing would work out. And we made a plastic hood and a plastic wing for the Honda Capa. Year. Everything is OK. Honda went to the new owner with these parts. Success, just go ahead!

And we immediately fell in love with this process. Thermoforming in tuning. A little (a lot!:))))) 3D modeling, milling – and a small-scale matrix is ready!

Unfortunately, none of the specialists were able to make our matrices. And we had to… build our own machine that allows “long” thermoforming. And this gave another plus. We are constantly improving our machine, our matrices, and our processes. But that’s not the most important thing either. The most important thing is business management. The quality depends on it. We use the most modern – KAIDZEN.

And about people. We like to hire young enthusiasts. Because it is enthusiasts who move our civilization forward. And we are proud of our employees.

About our production and our history

In 2018, we started the first thermoforming experiments.

Many people said that nothing would work out. And we made a plastic hood and a plastic wing for the Honda Capa. Year. Everything is OK. Honda went to the new owner with these parts. Success, just go ahead!

And we immediately fell in love with this process. Thermoforming in tuning. A little (a lot!:))))) 3D modeling, milling – and a small-scale matrix is ready!

Unfortunately, none of the specialists were able to make our matrices. And we had to… build our own machine that allows “long” thermoforming. And this gave another plus. We are constantly improving our machine, our matrices, and our processes. But that’s not the most important thing either. The most important thing is business management. The quality depends on it. We use the most modern – KAIDZEN.

And about people. We like to hire young enthusiasts. Because it is enthusiasts who move our civilization forward. And we are proud of our employees.

- Car brands serviced

- Satisfied customers

- Orders

- Types of parts are made

- Countries from which orders were received

- Parts have been manufactured over the entire time

- Car brands serviced

- Satisfied customers

- Orders

- Types of parts are made

- Countries from which orders were received

- Parts have been manufactured over the entire time

Reasons for pride

We are manufacturers from 2018

We have cool original ABS plastic production technologies

We have created a unique machine

Options

Vents

Without

Big vents

Chrome or black M vents

Surface

Matte

Ordinary

Comparison

Our price

We guarantee

We value our reputation among BMW fans.

Our future depends on it!

- High quality

- Best price

- Replacement of production/shipping defects

- Delivery on time

We guarantee

We value our reputation among BMW fans.

Our future depends on it!

- High quality

- Best price

- Replacement of production/shipping defects

- Delivery on time

Installation Instructions

Two way of installation.

Light and full versions.

2. FULL VERSION: Install it in a car service station using body cutting and welding.

Install attention! The holes in the plastic should be 1 mm larger than the fastener.

Installation Instructions

Two way of installation. Light and full versions.

1. LIGHT VERSION:

Install it on top of the car body, even in your garage.

2. FULL VERSION:

Install it in a car service station using body cutting and welding.

How work online support

We make the part. We do not store parts to reduce cost.

We pack and ship.

You receive, install, send a photo. If you have a questions, ask.

How we make Wide Body for BMW e46

What is the kit made of?

Made of ABS plastic. It is a unique three-component composite.

- Acrylic and styrene form a three-dimensional lattice. It gives rigidity, wear resistance of plastic.

- Butadiene molecules are located inside this lattice. They give the elasticity of plastic.

- Therefore, ABS plastic is the leader in fire resistance, impact resistance, frost resistance and chemical resistance.

- ABS plastic is better than polypropylene, polyethylene, polystyrene and other types of plastics.

What is the kit made of?

Made of ABS plastic. It is a unique three-component composite.

- Acrylic and styrene form a three-dimensional lattice. It gives rigidity, wear resistance of plastic.

- Butadiene molecules are located inside this lattice. They give the elasticity of plastic.

- Therefore, ABS plastic is the leader in fire resistance, impact resistance, frost resistance and chemical resistance.

- ABS plastic is better than polypropylene, polyethylene, polystyrene and other types of plastics.

ABS plastic vs Fiberglass

ABS plastic is exactly the right size

Fiberglass not

ABS plastic doesn't change shape every year

Fiberglass not

ABS plastic has a smooth surface, does not require putty

Fiberglass not

Feedback

Environmental

Collect

The plastic sections are collected by type and stored in such a way that they are protected from contamination

Recycling

Recycling means the processing of recyclable materials into new raw materials.

Conserving

Plastics can usually be recycled very well, as long as certain conditions are met.

FAQ

How will the goods be packed upon delivery?

All our items are packed in a five-layer cardboard box. There is a frame inside of 5-mm corners for safety. All parts are fixed inside the box.

How fast is the delivery?

USA is 2-4 week, Europe is a 1-3 week. Another lands pls ask us.

Is the plastic durable? What kind of plastic is used?

Modern ABS plastic. Well holds punches. If the impact was so strong that there is a crack, please contact us!

Can I install by myself or should I contact the service station?

You can install this on screws or rivets yourself in the garage. Or in a car service station with the cutting out of regular fender arches

Can there be elements in a different color?

We only produce black. You can paint in your color. Plastic is well painted. Or use tape for cars.

I have to think about it. For how long do you plan to release?

We do not know. Till the matrix is destroyed.

I like the original details. Do you know where to get it?

Search on the Internet. But be careful when installing – butadiene has evaporated from plastic over 30 years. The plastic has become as brittle as chips. You risk being left with several pieces of the grill on your hands during installation.

Is this part compatible with my modification BMW?

Pls send us a photo of your car